cnc in your garage

The X2MM CNC CONVERSION KIT... can help Engineers, Small Business Owners, Inventors, Gunsmiths, Machinist, Engineering Students, Jewelers, and Little Machine Shop Owners… Get into CNC… faster and easier… than they ever thought possible. Why not find out what the X2MM CNC CONVERSION KIT can do for you at my own risk!

From Sergio's Messy Desk

Wednesday, 2:21 pm

North Bank of the Columbia River, U.S.A.

Dear friend, we need to talk.

But first, let me say I am no advertising guy, so I will have to tell you about it in my own words with no nonsense.

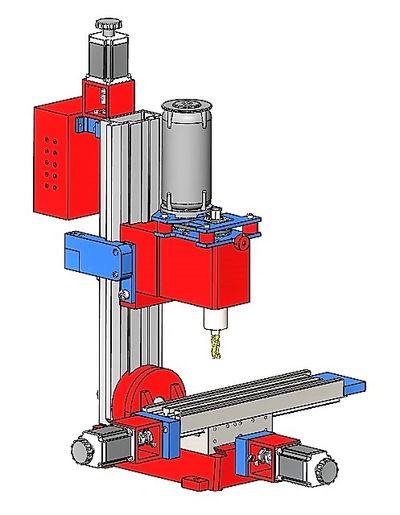

Hi, I'm Sergio, a mechanical engineer with 20+ years of machine design expertise. If you have been looking to convert your X2 mini mill to CNC... or... if you have been researching for a Desktop CNC milling machine chances are you have heard of me. (If not, hang with me for just a few seconds here. And I’ll show you how to turn your $729.99 Harbor Freight X2 Mini Mill into an almost $5,000+ Desktop CNC milling machine.)

Sounds too good to be true, doesn’t? Well, it’s not. And if you are serious about converting your X2 mini mill to CNC…(because this is only going to work if you are)…then sit back and let me explain what’s going on.

One more thing: I am basically a private guy and just an introverted engineer. But in order to get this important message out, I’ve been forced to put away all shyness and humility. So let me just lay it out:

I carefully designed and engineered the fast and easy-to-install X2MM CNC KIT, a unique CNC conversion kit for X2 mini mills - that you can switch from CNC to manual mode.

The X2MM CNC KIT is also a great option for guys who cannot afford or do not want to pay $5,000–$15,000 for a CNC desktop milling machine. And unlike the kits you've seen sold and on YouTube (that are notorious for binding) this kit is specifically-engineered not to bind… and you gain (not lose) 1.37” of Z-axis travel (but gaining an extra 3.37" of Z-axis travel is doable with block risers)… Plus: this CNC kit is the ONLY of its kind that can boost column stiffness — and much more.

***Take Note: On a limited basis, I offer ready-to-run X2 Mini Mill Desktop CNC machines...everything you need is included. Plus: I also offer exclusive CNC training videos to get you into CNC... as fast, as humanly possible. (Contact me. It is just that simple, friend).

WHAT IS THE X2MM CNC KIT?

The X2MM CNC KIT is a newbie-proof mechanical ‘plug-and-play’ kit. This original CNC conversion kit helps X2 mini mill owners save thousands of dollars by retrofitting their own mill… instead of paying $5,000 for a new CNC desktop mill.

And… the X2MM CNC KIT is the fast-track for X2 mini mill owners to get into the exciting world of CNC. All you need is 3-hrs and do a few alignments. (You can do it this afternoon, in fact).

But… did you know that a CNC converted X2 mini mill (with the X2MM CNC KIT) can do practically anything that a $5,000 CNC desktop mill can do?

In brief, the X2MM CNC KIT offers many exclusive features not found in any other kit. But that’s just part of the story… keep reading to find out more.

WHY THE X2MM CNC KIT IS BETTER

The X2MM CNC KIT is designed by an engineer with over 15 years of machine design expertise, not by an amateur that lacks the experience of sound design.

Here’s why it matters: Kits designed by amateurs cause binding. Why? Because they’re not engineers – they don’t know the fundamental (but critical) design principles.

Example, having three bearings on one shaft will cause binding. Why? Because the third bearing will never line-up perfectly. Yes, you could loosen and re-tighten the bearing blocks, but the shaft will bow… which kills bearing life.

Other CNC Kits appear to do the same as the X2MM CNC KIT. Don’t be confused. The X2MM CNC KIT is specially-engineered not to cause binding (when properly installed).

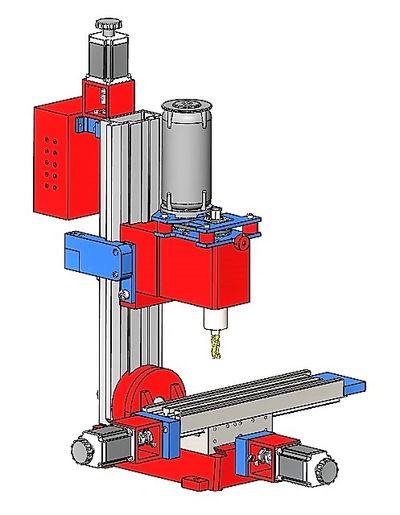

Every detail — from the custom-designed Z axis column to the carefully ‘hand-fitted’ ball nuts to the 1.37” extra Z axis travel — is engineered to boost column stiffness (reduce vibration) and repeat (to ballscrew tolerance). It reflects an engineering obsession to exceed expectations. You can’t design an X2MM CNC KIT like this one if you don’t design and engineer it that way from the start.

The result: a carefully engineered X2MM CNC KIT that exceeds expectations and turns a $700+ X2 mini mill into an almost $5,000 CNC desktop mill… without the $5,000 price tag

COLUMN STIFFNESS BOOST!

Why does a stiffer column matter? Because it reduces machine vibration – which is critical for machining tight tolerance parts, and for superior surface part finish.

One thing is for sure: the X2MM CNC KIT is designed to boost the column stiffness… and… it’s the only kit that can do this!

And there’s more: the X2MM CNC KIT has been cleverly designed to keep the Z axis ball screw away from chips and coolant. If chips get into the ball-nut, it will cause binding, downtime, and costly premature wear. Plus… this kit eliminates the need for a Z axis chip guard.

MORE Z-AXIS TRAVEL

The X2MM CNCN KIT is the only kit (as far as I know) that will gain you an extra 1.37” of Z axis travel – other kits rob you 1.37” of Z axis travel!

Here’s why the extra 1.37” matters: The Z axis travel (X2 mill) ranges from 8” to 11”. So when you swap long drill bits – its guaranteed that the bit will get in the way of the workpiece. Which means you have to move the mill table (loose tool position)… or worse… remove the workpiece (relocate the workpiece and tool position)!

Here’s the question: Can the machine return to 0,0,0 consistently after an operation? If you lose your ''0'' position, you have no idea where the mill is – this leads to errors in machine position and re-aligning the workpiece.

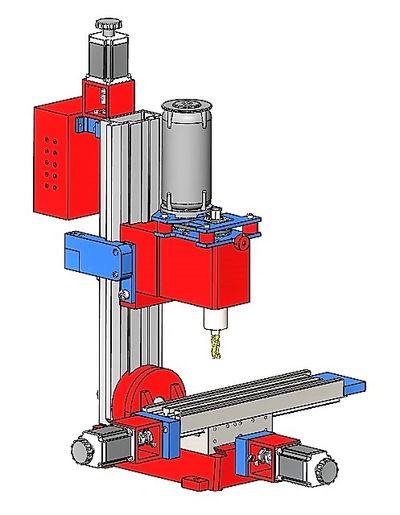

PRECISION-MACHINED KIT

The X2MM CNC KIT is precision-machined to assemble without binding, from the bearing blocks to the ball screws – everything is machined to exact specification. I have taken no shortcuts.

The X2MM CNC KIT is shipped to you pre-assembled (X Y Z axis) – this convenient time-saver guarantees your kit is shipped to you assembled correctly.

A well-built X2 CNC mini mill requires precision parts and quality components for utmost performance, else you just have a toy.

PRECISION GRADE C7 - BALLSCREWS & NUTS

The X2MM CNC KIT uses grade C7 precision rolled ball screws and nuts for a precision (butter-smooth) running fit...on ALL 3-axis.

for achieving a repeatability of ± .001” (or better).

Warning: Too much backlash is considered bad news... cuz it affects machine stiffness, plus... it is also hard on cutting tool life, repeatability, and machines parts.

Look: you can bet on machined circles and diagonal cuts to be out of spec if you have too much ball screw backlash. Why? Software (like Mach3) although it can compensates for backlash.... just cannot compensate (that well) for too much backlash errors.

HELICAL COUPLINGS (ZERO BACKLASH COUPLING)

Designers who use rigid (one-piece) couplers on small CNC machines – either lack design experience, or they want the cheapest route (or both). But this setup murders the stepper motors and bearing life.

Instead, the X2MM CNC KIT uses helical couplings for zero backlash (no play) – which are superior in handling parallel, axial, and angular misalignment.

And unlike other shaft couplers, these helical couplings handle more holding torque versus set screw couplings… without marring the shaft.

NO CHIPS ON HELICAL COUPLINGS

Using 4X round (or hex) spacers is a common (cheap) setup to hold stepper motors. But aligning the motor to the ball screw is awkward, slow, and misalignment will occur... plus chips will clog the coupling which may hinder coupling performance.

And worse: this method is not stiffer than using a square-type motor holders. Remember: stiffness is key... especially when IF your motors are running at higher speeds, which can cause resonance frequencies.

As a result — the X2MM CNC KIT offers a much better solution versus using 4X post to hold the motor. By using square motor mounts (which yields elegant sleek lines) the main function is to offer superior (and much stiffer) motor mounts. Plus: it also keeps hot oily chips away from the shaft couplers.

Warning: The 4X post approach is notorious for clogging the setscrews of shaft the couplers, which is NOT desired.

STIFF BEARINGS

Bearings are one of most critical components. Per ASTM’s rolling element standards, “installation and mounting errors accounts for 27% of all failures and 43% accounts for lack of lubrication”. Bearings that fit too tight (or too loose) on a shaft will cause premature bearing wear and wobbly looking finished parts.

The X2MM CNC KIT replaces the stock thrust bearings with robust double row angular contact bearings on all pillow blocks. This beefy setup yields high radial and high thrust rigidity, and unlike the stock un-sealed thrust bearings, the angular contact bearings are sealed to keep chips away – and to keep the bearings greased.

Unlike the stock open thrust bearings of the X2 mini mill, there’s a high chance for chips to enter the bearings, and for grease to ooze out. (Remember: 43% of bearing failure accounts for no lube!).

HOW TO SAVE $100/HR

It doesn’t matter if you’re cutting aluminum, steel, plastic – to make robots, guns, R/C, molds or jewelry. You need CNC. And a CNC converted X2 mini mill (with the X2MM CNC KIT) is a capable and indispensable investment.

A typical CNC shop rate is $100/hour. And you will never have to pay CNC shops $100/hr or wait on machine shops ever again!

The X2MM CNCN KIT is a small investment that is guaranteed to pay for itself in just a couple of hours. (What’s wrong with starting your side hustle on eBay to sell your CNC creations?)

RIGOROUS QA INSPECTION

The X2MM CNC KIT is hand-assembled from the ground up. Every screw is torqued down to just the right level before it is finished, then tested, and then it must pass a rigorous 14-point QA (Quality Assurance) inspection – no exception.

The $6,018,084 Dead Man Lesson: My past employer lost a $6,018,084 lawsuit because of a quality defect (that allegdly) led to a man’s death. That was the BAD news.

But the good news came by way of my QA/WI documents. In fact, these documents received high praise by the corporate lawyers (et al.) that handled the lawsuit. Why? The lawyers claimed that my pictorial documents were easy-to-follow and made a complex process - simple... so much, that the lawyers felt as if they could also setup the machines, too.

Here's why I bring it up:

An X2 CNC mini mill may not cause you to lose your life. But the lesson here is that – details do matter – in fact, they matter a whole lot!

Listen: inspecting parts is not fun stuff, but I've learned that being meticulous can lead to life or death... whether it be a human life or a CNC machine.

LIVE-SUPPORT (SE HABLA ESPAÑOL)

If you have any questions after (or before) you have installed the X2MM CNC KIT you can contact me by email or by phone.

After all… I’m the only CNC guy on the market that offers ‘live-tech support’… in English and Spanish… either way, I got your back!

As a small favor, I only ask you send me photos, testimonials or let me know what’s up (to brag… or… to complain) about how the X2MM CNC KIT is working for yah.

NO SPECIAL INSTALLATION REQUIRED

Did you know that you can turn your X2 mini mill into a CNC desktop mill with only a few screws?

There’s no guesswork installing the X2MM CNC KIT – it’s fast and easy – you don’t need special tools, you don’t need to grind, and you only have to pre-tap two holes – and you’ll need hex wrenches. (optional: crack open a cold one).

Just tap two extra holes... if you want to boost the column stiffness, and then just make a few alignment checks. (You’ll get easy-to-follow alignment techniques… plus I offer ‘live-support’ to help you along the way).

*PRICING* OF ONE-OF-A-KIND CNC CONVERSION KITS

Here are 3 great CNC options: BAREBONE and STRONGBACK and ELITE:

*** USA SHIPPING COST... $55/70+ (w/ tracking) ***

=======================================

$847: The STANDARD - 3X-Axis (No-Bind) CNC Kit

This CNC kit is Specifically-Engineered for X2 Mini Mill Machines is a superior choice versus the other CNC Conversion kits begin sold that are designed by amateurs that are notorious for binding (especially in the Z-axis).

- 3X Ballscrews C7, Precision (0.0015+"/foot)

- 3X Bearing Assemblies

- 3X Motor (NEMA) Hold Mounts (you provide motors)

- Y-Axis CNC Non-Chip Clog Cover - replaces front rubber accordion cover

- You provide: Motors, Shaft Couples, CNC Electronics, Software, CAM, Tooling, Vice, etc...

The heavy-duty, robust stepper motors that I use are specifically-designed with a low inductance… which ensures higher-torque throughout the rpm scale. (Compared to the other cheaper stepper motors… with higher torque ratings… these bad-boy pack the best overall CNC machine performance… plus, they can be ran at crazy fast IPM… without stalling).

More:

The stepper cables that I use are shielded… which reduce electrical noise… ensuring a near bullet-proof, overall electrical CNC solution. Isn’t that something?

(NOTE: You can also pick-n-choose options from the list below, too.)

*** USA SHIPPING COST: $55/70+ (w/ tracking) ***

=======================================

$997: The STRONGBACK - 3X-Axis (No Bind) CNC Kit

This CNC kit is Specifically-Engineered for X2 Mini Mill Machines is a robust upgrade to the BAREBONE – it features an innovative, stiffer Z-axis (8X Angular Contact Bearings) setup that is specifically-engineered to reduce machine vibration (surface finish) and resonant frequencies (high machine vibration)... and much (much) more, including:

Exclusive CNC Kit... including, no-bind smooth travel, heavy-duty Z-axis.

- 3X Ballscrews C7, Precision (0.0015+"/foot)

- 4X Bearing Assemblies

- 3X Motor NEMA Mounts (you provide motors)

- Y-Axis CNC Non-Chip Clog Cover - replaces front rubber accordion cover

- Z-axis Stiffener re-enforcement bar

- Z-axis Column Cover

- 2X Anti-rotation Column Mechanical Stops (rotating column only)

The heavy-duty, robust stepper motors that I use are specifically-designed with a low inductance… which ensures higher-torque throughout the rpm scale. (Compared to the other cheaper stepper motors… with higher torque ratings… these bad-boy pack the best overall CNC machine performance… plus, they can be ran at crazy fast IPM… without stalling).

More:

The stepper cables that I use are shielded… which reduce electrical noise… ensuring a near bullet-proof, overall electrical CNC solution. Isn’t that something?

You provide: Motors, Shaft Couples, CNC Electronics, Software, CAM, Tooling, Vice, etc...

(NOTE: You can also pick-n-choose options from the list below, too.)

*** USA SHIPPING COST: $55/70+ (w/ tracking) ***

=======================================

3-AXIS CNC Box (Pricing Varies - Based on Options):

- CNC CONTROL BOX (USB or Ethernet Connection) - Plug & Play CNC electronics in to get you into CNC — fast. This CNC electrical solution is designed to save you time — and takes away the hours of wiring frustration, choosing electronics, etc..

- 3X STEPPER MOTORS - Powerful Motors.

- Spindle (VFD) Connection - If you want to control your spindle (Fwd/Rev/Stop/Start)... This is usually only for Turnkey CNC Mini Mills.

- Home/Limit Switch Connection - If you get sensors from me, I'll modify your CNC kit for FREE.

- And a whole bunch more...

The heavy-duty, robust stepper motors that I use are specifically-designed with a low inductance… which ensures higher-torque throughout the rpm scale. (Compared to the other cheaper stepper motors… with higher torque ratings… these bad-boy pack the best overall CNC machine performance… plus, they can be ran at crazy fast IPM… without stalling).

More:

The stepper cables that I use are shielded… which reduce electrical noise… ensuring a near bullet-proof, overall electrical CNC solution. Isn’t that something?

4 & 5 & 6 AXIS CNC Electrical Box... Available on Request:

Additional Cost.

=======================================

Additional CNC Enhancement Options:

- LIMIT/HOME SWITCH CONNECTION BOX W/ SENSORS

- DIGITAL TACHOMETER

- FWD/REV - Switch for Hi-Torque Spindle

- CUT FORCE METER (VOLT/AMP)

- LED SPINDLE LIGHT

- LIMIT SWITCH CNC KIT MODIFICATION

- FWD/REV POT SWITCH - BRUSH LESS/NON BRUSH LESS MOTOR

- ANTI-COLUMN ROTATION STOPS

- LAPTOP/NOTEBOOK W/ MACH3 SOFTWARE

- And a lot more...

=======================================

$3,997 (Standard): X2 CNC Mini Mill Machine— READY TO RUN

- CNC CONTROL BOX - Plug & Play CNC electronics in a nice compact package to help you get into CNC—fast. This CNC electrical solution is designed to save you time—and it takes only a few minutes to setup. The CNC Brain Box is a fast-track solution that will save you hours of frustration. No need to worry about bad wiring, picking electronics, and on and on).

- LED Spindle Light

- CNC Software - Mach3

- Digital Tachometer

- Quality (high switching) Home Limit Sensors (Non-Contact)

==>>> YOU PAY SHIPPING! <<<===

*** USA SHIPPING COST: Variable (~ $200/350+... w/ tracking w/ insurance) ***

THERE ARE NO REFUNDS & ALL SALES ARE FINAL...

All right, if you are serious about getting into CNC, use the link below while these rare-quality CNC Conversion Kits are still available...

Your CNC amigo,

Sergio @ CNC-MiniMill.com

(Se Habla Español)

(PS): Contact me right now for questions, comments, give me props, hate mail, trolling, etc...(it don't matter)... just contacat me and lets talk.

(PSS): I ONLY make CNC Kits in tiny batches... it is FIRST COME, BEST SERVED. (No, I will not hold your CNC kit ...after you get back from your vacations, remodel your home, etc... unless you prepay for it).

Plus... I ONLY get to work on your CNC project after payment clears.

It is not rare that I get a "false-alarm" from guys supposedly wanting my CNC help. What is a "false alarm"?

That's the guys that seem serious about getting into CNC... but then nothing ever happens on their end.

As a result... I ONLY get to work on your CNC project... after payment clears. No Exceptions.

cnc near me X2 cnc conversion kit for mini mill * best mini mill for cnc conversion harbor freight mini mill cnc conversion kit GRIZZLY# G8689 * HARBOR FREIGHT mini mill # 44991 * sieg x2d mini mill * Little Machine Shop # 3960 3990 * harbor freight mini mill cnc conversion kit * mini mill cnc conversion kit * cnc conversion kit for mini mill * x2 cnc conversion kit for mini mill

Desktop Home CNC Mill Machines